Ignition Table

Click on the 'Generate Advance Table' button: A 'pop-up' window will open containing the.table formatted text (you may have to disable any 'pop-up stopping' software). If you get an error alert instead, you will have to correct your input values before continuing. Diagnose hot-spot formation and ignition. X-rayemission, whichis the basis formany widelyusedICFdiagnostics,dependsonthe spatial andtemporal profiles ofthe plasma density, ionization state, and electron tem-perature. During an ICF implosion, the electron andion temperatures can be quite different, andmixingoftarget components.

Part Throttle Tuning

This article outlines the steps taken to fix a part throttle tuning issue. The vehicle used was a EG Civic with a turbo-charged GSR engine, running about 9 lbs boost. Performance under boost was good, but at part throttle the vehicle had a hesitation at around 3000 rpm while cursing. Fuel consumption was high, either in open loop or closed loop. After approximately 90 minutes part throttle tuning using a wide band o2 sensor, the vehicle drove much better.

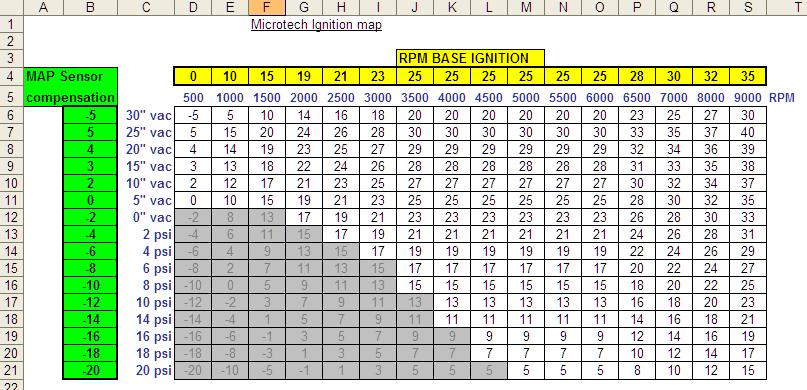

Ignition Tables

A common problem is too little ignition advance at part throttle, especially at about 10' vacuum and 1000 - 3000 rpm. This will cause difficulty tuning the fuel tables, as the engine becomes very sensitive to small changes in fuelling if there is not enough ignition advance. Driving the car we could feel a lot of surging under light throttle, so ignition was advanced at part throttle.

The original low speed ignition table.

The final low speed ignition table. Care was taken not to increase overall advance, nor add advance where the engine might ping. The peak increase was from 20 to 29 degrees at 1750 rpm and 5 inches vacuum. This change made a huge difference to the way the car ran, with a low more engine output below 3000 rpm.

Fuel Tables

The 2D view is a good way of evaluating how well tuned a table is. Lines should not cross each other, and should be evenly spaced. We had to alter the low speed fuel tables only.

The original low speed fuel table. The vehicle actually ran quite well from this table once ignition advance was increased, but you can clearly see that the table is not good, with inconsistent fuelling .

The final low speed cam fuel table, are tuning using a wide band O2 sensor. The pattern of lines in the 2d view is very typical of a well tuned engine. The lines representing the bottom four columns should be parallel and evenly spaced, the middle two columns are spaced further apart but are also parallel, and the top four columns are evenly spaced. The lowest column should be about half way between the second column and the bottom of the graph.

It is important not to make the fuel tables too rich in the bottom two columns, otherwise in closed loop the ECU will lean out the mixture 20-30%, which results in hesitation when the throttle is applied after decelerating briefly.

Miscellaneous Changes

Idle speed was increased from 750 rpm to 850 rpm.

VTEC was increased from 4000 rpm to 5200 rpm.

The minimum engine load from VTEC was increased to 950 mbar.

Other Comments

The vehicle had an autometer air/fuel gauge connected to the stock O2 sensor. The combination of an old O2 sensor and the air/fuel gauge resulted in the O2 sensor feedback voltage being lower than normal. This made the O2 sensor response slow, and causes the engine to run rich (as it is getting false lean feedback via the O2 sensor).

The O2 sensor feedback voltage was incorrect, which was traced to a dirty wiring connector on the right hand strut tower. It is recommended to clean the main wiring connectors with contact cleaner from time to time.

Last updated: 2 July, 2016

Table of Contents

Common Ignition Problems

- Pinging

Pinging occurs when the fuel mixture in the cylinder ignites and completes its burn before the piston reaches the maximum compression point in its travel. It sounds as though a handful of marbles were dropped into your engine and generally occurs under hard acceleration under load.

There are several possible causes of pinging. Among them:

- Fuel octane too low

Fuel octane is a measure of the ability of the gas to spontaneously ignite. (For more information on octane, see the Gasoline FAQ.) When the octane is too low, the fuel in the cylinder burns too quickly causing ping. The stock Miata is designed to run on 87 octane fuel. If you have modified your intake tract, your Miata may require higher octane fuel than 87.

- Timing advanced too far

Advanced timing means that the spark which ignites the fuel mixture in the cylinder occurs before the piston reaches top dead center of its excursion. Factory spec for the Miata specifies standard timing as 10° before top dead center (10° BTDC) ±1° at idle speed (850 rpm). If your timing is advanced more than this, you may experience pinging under some conditions.

- Dirty spark plugs

- Metallic burr in cylinder

Deposits on your spark plugs and burrs in the cylinder or cylinder head can begin to glow due to the heat of combustion. The glowing metal then serves to ignite the fuel-air mixture before the spark occurs causing detonation or ping. Be sure your plugs are free of deposits.

- Spark plug heat range incorrect

The size of ceramic insulation on a spark plug determines the heat range of the plug. If the heat range is too high (longer insulator) the plug itself can begin to overheat causing detonation of the fuel-air mixture. If other methods fail, you might try switching to a plug designed to run cooler. Typically, a colder plug is better if most of your driving is long distance, high speed travel. For stop and go driving, a hotter plug is supposedly better. OEM plugs usually are somewhere in the middle.

Hesitation

Common Problem! The factory ignition wires on the Miata only seem to last between 30,000 and 50,000 miles. If you are experiencing misfiring and hesitation and you haven't changed your wires, this is most likely the cause. Change the wires! In case you forget which plugs is which, refer to the firing order diagram below.

This is caused by breakdown of the insulation on the wires which results in the spark arcing through the insulation to the metal valve cover instead of through the spark plug electrodes.

Dave Weckerle sent in this bit of information regarding hesitation. Although the wires are the most common cause, if you have a '96 model, you might try this solution:

Last April I purchased a 1996 Miata. Unfortunately it didn't run like the 1995 that I test drove. Mine would surge or hesitate on acceleration and at normal cruising speed. I spent several hours in the shop where they tried advancing the TPI to .8 and several other little 'tricks' none of which worked. I was then told that the problem was normal for the 1996 model because one of their factory service reps was having the same problem. Yesterday I read the article about advancing the timing to 14 or 16 degrees and decided to try it. The car now runs like I think it should. No surge or hesitation.

There is another possible cause for hesitation and poor idling:

Water in the engine - if you clean the engine bay with a pressure hose and spray the top of the engine block, you may have troubles. The rubber seals on top of the spark plugs aren't so great, so some water can seep into the cylinders, particularly the no. 1 cylinder. Once it dries out, everything should be fine. You may need to blast the water out with high pressure air.

Stalling

Many owners have complained about stalling or being on the verge of stalling after stopping at a light. The most common cause seems to be the idle speed. The Miata idle speed is specified as 850 ±50 RPM. If you have a tendancy to stall, try adjusting the idle speed to the maximum of the range or 900 RPM. Adjust the idle speed screw.

Uneven Running

If your Miata is running unevenly, sometimes stalling, sometimes hesitating, there could be another problem. Your timing belt may have jumped a tooth or worse, your crank shaft may be broken.

An easy way to check is, pull #1 spark plug, and drop the dipstick down the hole. Turn the motor by hand and watch the dipstick until it peaks at top dead center. This will tell you the crank shaft is at TDC. Now check to see where the timing mark on the crank pulley lines up. If it is to the left of 0, then the key way may be worn or the timing belt may have jumped a tooth (or was improperly installed). In either case, you need to pull off the timing belt. While its off, check the keyway on the crank nose.

There is another possible cause for hesitation and poor idling:

Water in the engine - if you clean the engine bay with a pressure hose and spray the top of the engine block, you may have troubles. The rubber seals on top of the spark plugs aren't so great, so some water can seep into the cylinders, particularly the no. 1 cylinder. Once it dries out, everything should be fine. You may need to blast the water out with high pressure air.

Power loss

- Timing retarded too far

When the timing is retarded to the point that combustion occurrs later than 9° BTDC (which means the timing is set to less than 9°), the combustion of the fuel-air mixture is no longer occurring at the most efficient time. The piston is already beginning to travel back down the cylinder when the combustion occurrs. The piston is therefore travelling a shorter distance under power which translates to power loss. The timing on a stock Miata should be set to 10° before top dead center (10° BTDC) ±1° at 850 RPM idle speed.

With a turbocharged or supercharged engine, this may not hold true. Set the timing based on the manufacturer's recommendations.

- Spark plug gap out of spec.

As spark plugs wear, the gap between the electrodes tends to get a bit wider. The standard gap on the Miata's spark plug should be 1mm. A wider gap may result in misfiring due to the voltage not being quite high enough to cause a spark across the electrodes.

Warning on Compression Checks

We received this message from Ryan Ruston:

I recently had a bad experience with the coil packs on my 1995 Miata. You may want to share this on the site.

I recently bought a 1995 Miata and had a friend do a compression check on the motor. He pulled the fuse for the fuel injection and proceeded to remove one spark plug and plug wire at a time and check the compression. When done, we put everything back together and the car wouldn't start. Turned out that the coil assemblies where fried. Apparently, leaving one of the plug wires open put too much of a strain on the ignitors and burned them out. Fortunately, we found a coil assembly from Mazmart in Atlanta for only $125. Now the car runs fine. The point is, don't do a compression check without either pulling the connectors from the coils or keeping a spark plug in the wire while turning over the engine. Hope this helps someone else.

Spark Plugs

- Splitfire Plugs

Although it has been reported in Miata Magazine that an increase of 1 or 2 horsepower can be achieved using Splitfire spark plugs, many owners report no discernable difference in performance. You should also read the Federal Trade Commission action involving Splitfire before making your decision. In addition to the substantially higher cost of Splitfires ($5 - $6 per plug instead of $1 - $2), there are two other problems that have been reported:

- The washer sometimes remains when the plug is removed.

The crush washer is not permanently mounted to the plug. This has resulted in the washer remaining behind when the spark plug is removed from the head. It then becomes necessary to use some sort of clever tool to retrieve the washer. - The boots on the ignition wires sometimes remain on the plugs.

The ceramic insulator on the spark plug has straight sides - not ridges like the factory NGK plugs. As a result, the rubber boots on the spark plug wires sometimes grabs the ceramic insulator so tightly that the boots stay behind when the wires are removed. When this happens, there is no way to fit a spark plug socket on the plug and therefore no way to remove the plug. (When this happened to me I had to use a scalpel to cut the rubber boot off the plugs and retrieve the pieces with a long tweezer.)

Some people have had better luck by using dielectric grease on the ceramic insulators and wire boots prior to installing the wires. I haven't tried it.

- The washer sometimes remains when the plug is removed.

- NGK, Bosch Platinum, others...

NGK plugs are OEM equipment. Some owners have reported better performance by using Bosch Platinum plugs, but any difference would be miniscule - under 1hp. It is highly unlikely that the difference would be detectible. Still, if you're autocrossing and need every extra bit of power, you may want to consider higher performance plugs.

Replacing Spark Plugs

Tools required:

- 5/8' Spark Plug Socket

- 6' Locking extension

- Torque wrench

- Gap tool

- anti-seize compound

- Silicone Grease (optional, but recommended)

How to change spark plugs:

- Remove Spark Plug wires from plugs

Do not grab the wires themselves! Remove the ignition wires by firmly grabbing the boot that seals the spark plug well. - Remove plugs

Using the spark plug socket and the 6' extension, carefully unscrew the plugs. Be careful not to drop any foreign matter into the wells. - Check gaps on new plugs

Most spark plugs come pre-gapped. Ensure that the gap is 1mm using the gap tool. - Apply a thin layer of anti-seize compound to plug threads

- Install plugs - don't tighten

Using just the 6' extension and the spark plug socket, (do not use a ratchet yet), carefully screw the new plugs into the engine. Be extremely careful not to cross thread the plug! Make them hand tight only. - Torque to spec

Using a torque wrench, tighten the spark plugs to 11-17 ft-lbs. - Apply Silicon Grease to inside of bottom seals of plug wires (i.e. inner surface of plug wire which mates to the ceramic insulators on the plugs)

- Re-install ignition wires and start it up!

Ignition Wires

The Miata ignition wires are, arguably, the weakest point in the car. As early as 20,000 miles, (but generally closer to 40,000 miles) the insulation begins to break down and develop small pinholes which result in the spark going through the pinhole to the block instead of across the electrodes of the spark plug. This problem surfaces as hesitation at low RPM.

The ignition wires in the Miata should be replaced every 50,000 miles or sooner if you begin to develop a low RPM hesitation or misfiring.

Factory wires vs. NGK

The blue NGK wires are clearly superior in longevity to the original black wires on the early Miata models. Newer models may come with the blue NGK wires. Even with the higher quality wires, eventually they will break down. There are several aftermarket companies which also make high performance wires, and others that make 'dubious' performance claims. Magnecor is considered a high performance wire. They also have an excellent writeup which debunks many of the claims made by less reputable companies.

Ignition Timing

Checking timing

Tools required

- Inductive Timing Light

- Jumper or paper clip

- External Tachometer

Begin by finding the big pulley on the front bottom of the engine, there should be a little hunk of plastic to the top right of it with markings on it. On the back rim of the pulley feel around until you find a notch in it. It may require turning the car on and off a few times until it is in a reachable location. When you find the mark, put a dot of White-Out or something on it to mark it (you know, the stuff that covers ink-pen errors). This photo shows the plastic thingy and the little etched timing notch.

Make sure all accessories (A/C, lights, radio, heater, etc.) are turned off and engine is warmed up to operating temperature.

Next, locate the diagnostics connector(close-up view) on the driver's side of the engine compartment near the air intake. It 'll be on the drivers side in plain sight. Pop it open and look for the GND and TEN places. Get a paperclip or hunk of wire, and while the engine is running shove it down into the correct GND and TEN holes. (This puts the on-board computer into the proper mode for setting the timing.) When you push it in there hard you may hear the engine slow down. Now check the tachometer (or if you don't have one, use the one on your dash) to see what its at. It should be around 850. If not, its easy to fix. Find the big screw over on top front of the intake (big metal thing on passenger side). It should be covered with a black rubber plug, but some are missing. Just turn that screw till you get your idle speed to 850 RPM.

Connect the timing light power cable to a source of 12volt power. Since the battery is not in the engine compartment, you should use the auxiliary power connector provided for this purpose. There is a blue connector which is not connected to anything located on the driver's side of the engine compartment close to the side of the car about halfway between the diagnostics connector and the headlight motor. Remove the dummy connector to expose the conductor. This is where the timing light positive red wire can be powered from. Connect the timing light ground connection (the black wire) to a suitable grounding point such as one of the unpainted bolts or other unpainted metal connected directly to the body. Put the inductive pickup around the number 1 spark plug wire which is the one closest to the front of the car. You don't have to pull the plug wire off. Be careful you don't let any of those dangling wires catch in the fan or belts.

Now make sure your car is idling at about 850 RPMS with jumper in place and everything connected. Turn the switch or pull the trigger or whatever on your timing light and watch that big pulley with the yellow or white timing mark. As the light flashes, it will make the marking on the pulley appear to 'stand still'. You will see the mark appear next to a certain spot on those plastic markings. Refer to the photo. The engraved mark should be hanging around right at the 10° BTDC mark. If not, first check your idle speed. Otherwise you will have to set the timing as described in the next section. Each mark represents 2 degrees of timing advance. Factory specification is 10° before top dead center (10° BTDC) ±1°. If it is not where you want it, be it 10° or advanced to 14° for a bit more power, you need to set the timing.

Setting timing

Note: The timing on the '99 Miata is not settable. The '99 engine is designed with variable timing and a knock sensor which will automatically retard the timing if the engine pings. However, someone has found a method to change the '99 timing (although we don't recommend it and we have no performance data to back it up.) Read about it here.

Tools required

- 12mm socket

- Socket wrench with articulated head (if possible)

- Timing light (Note: Many timing lights with tach/advance measurement features are a bit confused by the double ignition pulse of the Miata. The use of the strobe is not confusing (it works out visually just fine) but the tach/advance meter will read double of what it should because of the double pulse. )

Set up your timing light and diagnostics jumper as described in 'Checking Timing' above. With the jumper installed, your idle should be about 850 RPM. If it is incorrect, adjust it with the idle air bypass screw located on the throttle body. The screw is under a black rubber cap. Clockwise lowers the idle, CCW raises it.

For 1.6 liter engines locate the crank angle sensor (close-up view) at the rear of the passenger side valve cover, close to the firewall. It is a circular metal unit that sits right on the rear of the valve cover. Locate the locking bolt for the sensor. This is on the lower side of the sensor bracket nearest to the passenger side. Using a 12mm wrench, loosen this bolt only enough to allow you to rotate the crank angle sensor. As the crank angle sensor is rotated (only a small amount at a time), you will see the timing change with the timing light. When you get the timing back in spec, tighten the lock bolt. (photo of CAS Lock Bolt on '97 1.8)

You can find the cam sensor on your 1.8 liter Miata by following the driver's side hump in the valve cover to the back of the head.

On the rear face of the head you will find a round unit with a multiplug on it. This is the sensor. There is one bolt with a twelve mm head on it that is the hold-down. If you were sitting in the driver's seat looking at the back of the head, the bolt is at about five o'clock. Don't forget to jump the TEN and GND pins in the diagnostic connector (close-up view) before setting.

Note: When rotating the CAS to adjust your timing be sure to check for leaks. You may also want to consider replacing the CAS o-ring seal. If the seal is old, the rotation of the CAS can lead to the seal being compromised. An oil leak will start under the CAS and then oil will deposit on the heater hose.

Use the correct painted dot on the crank pulley. Depending on what year you have, it may be a white mark, or it may be a yellow mark.

- 89-93 a white mark at TDC.

- 94 a yellow mark at TDC and a white mark at 10 degrees BTDC.

- 95 a white mark at 10 degrees BTDC and a yellow mark at TDC. (Some people have said there is no yellow mark.)

- 96-98 same as 94.

- 99 timing is not adjustable

Jared Stack points out: It's best to set the timing when the car has warmed up to the point where the idle has settled and the engine is up to operating temp, but is still relatively cold. The motivation for doing this is to make sure that when you check your timing that the radiator fan is not running. If it activates, the timing will be retarded by 1-2 degrees. The consequence of setting it at this point is when you are on the open road at speed the fan usually won't be running as much and the timing will be higher than what you thought it was set to. There should be a fuse for the radiator fan... just make sure you put it back when finished. :-)

If you tweak the idle this will affect the baseline value of the timing. Tweak idle with jumper in place and correct the timing. After adjusting the idle (improperly, without the jumper) to compensate for the current draw of the Hella H4's, my timing was retarded by about 3 degrees!

Harry Sue has a good timing writeup with more photos at http://www.rivercityroad.com/garage/timing.html

Rick Fischer (rickfisc@ozemail.com.au) helps clarify Jared's statement:

Timing must be set with the motor in a no load condition at the specified idle speed. Electrical loading of the alternator sucks horsepower, drag on the motor - slows it down. Therefore the revs aren't right. The timing mark may move when the motor drops revs but that is a function of the rev drop not the electrical load.

The Hellas did not affect his timing by 3 degrees the current draw and motor slowing did. Advancing the timing to compensate will have just advanced his timing - period.

This may cause problems if the person doing the retiming is not across the general principles of ignition timing, and accepts Mr. Stack's comments on their face value. Someone advancing their timing to the 16 or 18 degree marks and then compensating for what they think is another factor may well over advance the timing to the point where detonation may occur; i.e. 16-18 plus 2 for the fans and 3 for lights = 21 to 23. The Pinging may well be a very expensive noise, breaking rings and cracking pistons in extreme occurences.

Very simply, time any motor - no load. No A/C, no lights, no fans.

- 89-93 a white mark at TDC.

- 94 a yellow mark at TDC and a white mark at 10 degrees BTDC.

- 95 a white mark at 10 degrees BTDC and a yellow mark at TDC. (Some people have said there is no yellow mark.)

- 96-98 same as 94.

- 99 timing is not adjustable.

Extra power by advancing

Most Miata engines can benefit from advancing the ignition timing. How far you can safely advance the timing will depend on several factors. One major factor is fuel octane. The higher the octane you are willing to buy, the more timing advance you will be able to run. Ambient temperature also plays a role--the hotter the weather, the less timing your engine will tolerate. Different Miatas also have their own idiosyncrasies about timing. As engines pile on the miles they develop an octane appetite from carbon deposits in the combustion chamber which can cause hot spots and actually raise the compression ratio of the engine by reducing the size of the combustion chamber.

Many enthusiasts have found that they gain a few extra horsepower by advancing the timing to 14° BTDC. Some have gone as high as 18° BTDC without problem. The difference between going from the stock 10° to 14° is much more noticeable than going from 14° to 18°. Ping is usually experienced under hard load driving - not idling in your driveway. So you'll have to set the timing and drive it for awhile before you really know the effects.

Ignition Table Perspective

Timing for Modified Intake Tract

If you've modified your air intake with the installation of a turbocharger, supercharger, Cold Air Intake, or other type of upgraded high flow intake system, the timing rules may change. You should follow the advice given by the manufacturer of your unit.

Idle Speed Adjustment

Bill Cardell from Flyin' Miata shares his method:

The stock tach is close enough for what you are doing. Just look at where you are idling without the jumper connected, before you mess with anything. That is the idle you want to end up with. After setting the timing (with jumper installed) adjust the air bypass screw on the throttle body to bring the idle to 850 (with the jumper still installed). The bypass screw is located under a black rubber plug on top of the throttle body. The throttle body is located on the passenger's side of the engine. The throttle cable goes to it. After setting the idle speed, double check your timing. I would suggest scribing a mark on the cam sensor *before* moving anything. This way you can return towards stock without hooking up the timing light again. I say this because despite what MM says, every Miata seems to tolerate a different amount of timing. If it pings just sneak back towards stock 'til it stops.

(Note: Photo above is for 1.6 engine. Front view, 1.8. Side view, 1.8.)

Phil Logan contributes:

The tacho connects to the IG terminal on the diagnostic connector.

The diagnostic connector is on the driver's side and is cunningly disguised as a DIAGNOSTIC CONNECTOR (close-up view) It's nice when things identify themselves :-)

Ignition Table Dataset

If you pop the lid of the diagnostic connector, you'll see a bunch of terminals and, inside the lid, a little diagram saying what the terminals are.

To set the idle, put a jumper wire between terminal TEN and ground, and connect the tacho to the IG terminal (that's towards the bottom right hand corner of the connector block. The TEN <- > ground shorting wire is necessary to properly set both idle and timing.

You may find, as I did, that when you connect the external tacho, the car's tacho reads zero - don't worry, you haven't broken it, it's just that most budget analogue meters have fairly low impedance and affect the tacho filter, so the internal tach doesn't see any pulses.

The idle speed adjuster (close-up view) is at the front of the intake manifold on the passenger side, and should be covered by rubber plug. When I did my timing, I hunted around for this plug for a bit before realising that the plug wasn't there and the speed adjuster screw was exposed. So look for either a likely looking recessed screw, or a rubber plug that looks like it's hiding one.

To increase the idle rate, turn the screw anti-clockwise. It looks like it's about half a turn for about 500 rpm. The manual I had said that the idle speed should be between 800 and 900 rpm, but I set mine a little higher to get rid of the idle-droop I was getting from time to time.

When you're all done, bung up the timing adjuster plug, remove the jumpers, clip the diagnostic connector top, drop the hood and have a blast.

I'm assuming your car is LHD. If not, things may be moved around a bit.

Robert Meushaw shares some of his experiences when working on accurately setting his idle speed.

As a matter of intellectual curiosity, I decided to investigate the correlation between the Miata tach reading and the IG- signal on the diagnostic connector. Fortunately I have a digital storage oscilloscope and a digital frequency measuring multimeter. The signal coming from the IG- test point is a pulse approximately 2 milliseconds in width and approx. 12 volts in amplitude. I measured the pulse frequency when the tach indicated that the car was idling between 700 and 1000 rpm. The scope reading and frequency meter reading indicated approximately 29 pulses/sec. Multiplying by 60 gave 1740 pulses/min., which is not correct. But, dividing by 2 gives 870 pulses/min which is about right. Therefore, the conversion from the IG- signal to rpm is

RPM = ( PPS x 60)/2 or PPS x 30

This is perhaps more effort than is needed to get a correct rpm reading, but inquiring minds want to know. Please note that these measurements were taken without shorting the TEN pin to ground, but the rpm signal correlation would still be the same.

Advancing the Timing on a '99 Miata

This was on a US-spec car in Puerto Rico. We have no additional information regarding performance, reliability, or anything else. Miata.net does notrecommend this procedure.

'I advance the ignition to 14 degrees on my '99. It's a matter to trick the ECU. How?, Repositioning the Crankshaft Position Sensor more upward. CPS is on the right down side of the Crankshaft Pulley. First, I disconnected the CPS connector, remove the undercover, then remove the CPS bolt. Once a time I got it out of the car I proceed to enlarge the hole (bottom side) of the CPS bolt in order to get the upward reposition. Using my portable Dremer I cut off ('bore') about 2-2.5mm from the integrated washer in the mentioned hole. Finally, I installed back the CPS having condider the following: Air gap between Pulley Plate teeths & CPS (Spec: 0.5-1.5 mm) and tightening torque of CPS bolt is 69.5-95.4 in-lbf. Past Specs were taken from the Miata'99 Workshop Manual.

Porsche 3.2 Ignition Table

After complete the installation. I used Timing light to check my new timing and SURPRISE!: timing is now oscillating between 14-16 degrees at idle instead of the factory oscillating 9-11 degrees.'